Serving Industries

Following Strict Quality Practices

Serving Industries

Following Strict Quality Practices

Services

We have the ability to adhere to close tolerances and produce high-quality parts with a high rate of repeatability. With working in the Aircraft and other industries our employees have the know how to follow strict quality practices for the creation of High-Quality and High-Precision parts.

Capabilities

Machining and Fabrication of different material groups (Stainless, Aluminum, Plastic, Titanium, Steel etc..)

- Computer Aided 3D Design Software.

- Computer Aided Manufacturing Software

- Prototype Design and Production

- Research and Development

Equipment

- Hyundai-WIA 5th Axis (CNC Mill)

- Okuma ES-v4020 (CNC Mill)

- Mitsubishi M-V5C (CNC Mill with 4th Axis)

- Mazak QTS-250 (CNC Lathe)

- Mazak QT-6T (CNC Lathe)

- FEMCO HL25N (CNC Lathe)

- Manual Machining Equipment

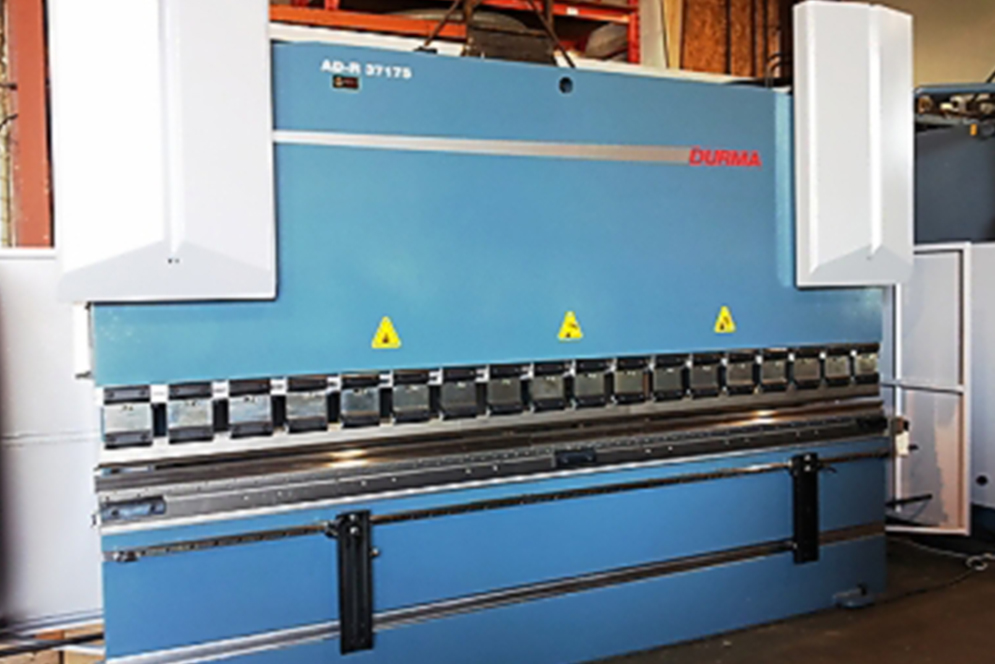

- DURMA ADS-R37175 CNC Hydraulic Press brake

- DURMA Shear

- Welding Equipment (TIG/MIG)

- Brushing equipment for Stainless Steel and Aluminum

- Sand Blasting

- Inspection Tools and Equipment

Our welders can use the following techniques

- TIG welding (Tungsten inert gas)

- MIG welding (Metal inert gas)

- Arc welding

We offer welding services on the following materials

- Stainless steelm

- Aluminum

- Titanium

- Cast iron

- Steel

Our typical turnaround times for welding will vary based on the size and type of material of your project. However, our customer service respects the time and needs of each and every customer.

Start Building Your Website Today!

Starting At Only